Beagle-Solar-A-Car

https://code.google.com/p/texas-instruments-intern-design-competition-2013/

Introduction

The aim of this project is to build a solar energy powered autonomous car. Resistive matching has been employed to extract maximum energy from a solar panel, with minimal complications. This is done in order to maximize the amount of energy that is transferred from the solar cell into a Li-ion battery. This battery is used to drive an H-bridge motor controller which is controlled through the BeagleBone.

Schematic

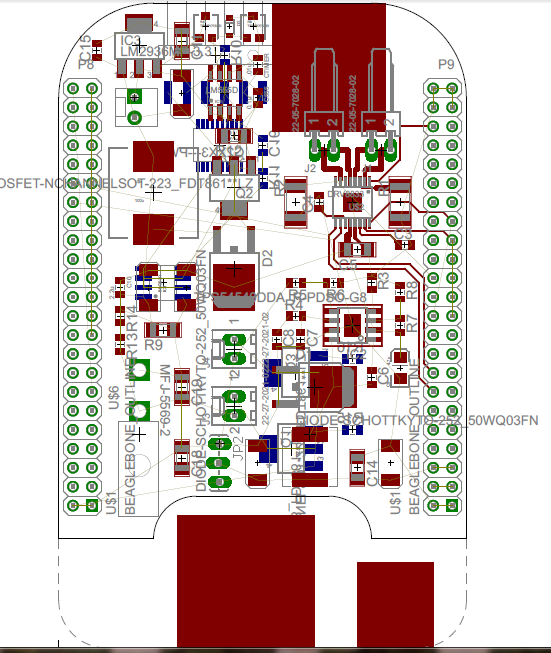

PCB

Code

Header File

#! /bin/sh#This script initializes the pin muxing modes to bring out the PWM and UART signals to the desired header pins.

#Must be executed manually from the command line after booting.

#Would be nice to have this done automatically at boot time, but I've had trouble finding a solution that works.

#Enable UART4 at header pins P9_11 (RX) and P9_13 (TX).

echo uart4 > /sys/devices/bone_capemgr.9/slots

echo am33xx_pwm > /sys/devices/bone_capemgr.9/slots

#Enable header pins for PWM0A at P9_31 respectively. (DC Motor)

echo bone_pwm_P9_31 > /sys/devices/bone_capemgr.9/slots

#Enable header pins for PWM1A at P9_14 respectively. (DC Motor)

echo bone_pwm_P9_14 > /sys/devices/bone_capemgr.9/slots

#Enable header pins for PWM2A at P8_19 respectively. (Servo)

echo bone_pwm_P8_19 > /sys/devices/bone_capemgr.9/slots

#Setup further options for UART communication

stty -F /dev/ttyO4 raw

#Poll UART4 for motor position and speed data without interrupting the main script timing

#while 1

#do

# cat /dev/ttyO4 > /var/lib/cloud9/rcvd.txt

#done

Main Code

var b = require('bonescript');var servo_per = 20000000; //20000000 ns = 50 Hz

var servo_pos = 0; //-100 is far left, 0 is center, 100 is far right

var servo_step = 10;

var sig_speed1 = 0;

var sig_speed2 = 0;

var zc_timeout1 = 10;

var zc_timeout2 = 10;

var motor1_per = 50000; //100000 ns = 20000 kHz

var motor2_per = 50000;

var motor1_dc = 50;

var motor2_dc = 80;

var motor1_step = 10;

var motor2_step = 10;

var motor1_state = 0; //1 for forward, 0 for stopped, -1 for reverse

var motor2_state = 0;

var motor_dc_max = 100;

//Initialize PWM periods and polarities

b.writeTextFile('/sys/devices/ocp.2/pwm_test_P8_19.14/period',JSON.stringify(servo_per));

b.writeTextFile('/sys/devices/ocp.2/pwm_test_P8_19.14/polarity','0');

b.writeTextFile('/sys/devices/ocp.2/pwm_test_P9_31.12/period',JSON.stringify(motor1_per));

b.writeTextFile('/sys/devices/ocp.2/pwm_test_P9_31.12/polarity','0');

b.writeTextFile('/sys/devices/ocp.2/pwm_test_P9_14.13/period',JSON.stringify(motor2_per));

b.writeTextFile('/sys/devices/ocp.2/pwm_test_P9_14.13/polarity','0');

b.pinMode('P9_29', b.OUTPUT);

b.pinMode('P9_16', b.OUTPUT);

b.pinMode('P9_42', b.OUTPUT);

b.digitalWrite('P9_29', b.LOW);

b.digitalWrite('P9_16', b.LOW);

b.digitalWrite('P9_42', b.HIGH);

setInterval(updatePos,10); //Loop every 5 ms

setInterval(rcvData,2000);

function rcvData()

{

if(sig_speed1 == 100)

{

sig_speed1 = -100;

}

else

{

sig_speed1 = 100;

}

if(sig_speed2 == 50)

{

sig_speed2 = -50;

}

else

{

sig_speed2 = 50;

}

}

function updatePos()

{

//Motor control - ramp up motor duty cycle instead of instantly responding to phone's commands

//Also briefly stop the motors at zero-cross before changing directions

//If P9_29/P9_16 is low, motor is currently ordered forward and PWM DC is normal (polarity = 0)

//If P9_29/P9_16 is high, motor is currently ordered reverse and PWM DC is inverted (polarity = 1)

//If motor is currently moving in the same direction it is commanded (no zero-touch or zero-cross)

if((motor1_state == 1 && sig_speed1 > 0) || (motor1_state == -1 && sig_speed1 < 0))

{

if(sig_speed1 * motor1_state > motor1_dc) //If duty cycle needs to increase

{

if(sig_speed1 * motor1_state - motor1_dc < motor1_step && sig_speed1 * motor1_state < motor_dc_max)

{

motor1_dc = sig_speed1 * motor1_state;

}

else if(motor1_dc + motor1_step < motor_dc_max)

{

motor1_dc += motor1_step;

}

else

{

motor1_dc = motor_dc_max;

}

}

else //If duty cycle needs to decrease (or stay the same)

{

if(motor1_dc - sig_speed1 * motor1_state < motor1_step)

{

motor1_dc = sig_speed1 * motor1_state;

}

else

{

TI Parts Used

Used to provide a gate-driving signal for the buck-boost

regulator. This is configured as an approximately 57KHz oscillator.

DRV8833 - 2A

Low Voltage Dual Brushed DC or Single Bipolar Stepper Motor Driver (PWM Ctrl)

LM2936 -

Ultra-Low Quiescent Current LDO Voltage Regulator

Used to provide a regulated 5V for the timer. This allows steady

operation at solar voltages up to 40V

TPS54360 - 60 V

Input, 3.5 A, Step-Down DC-DC Converter with Eco-mode

Used to provide an efficient 5V for the BeagleBone Black at

battery voltages as low as 6V.

Good job :) Congratulations!

ReplyDelete